A production order is used to define the material to be produced, plant location where production has to be done, date and time of production, and quantity of goods required. A Production Order also defines which components and sequence of operations are to b used and how the order costs are to be settled.

BOM and routing data of the materials are copied into the production order, which determines the list of components and operational data in the order.

Following are the key steps involved in Production Order confirmation.

- The first step is to convert a planned order to a production order. When you create a Production Order, type is defined in SAP PP system.

- To start the production process, it is necessary to issue a Production order. Till a production order is not released, the execution of production process does not start.

- Issuing goods is required for providing the goods to execute the Production order. Once goods are issued, the document number can be updated in the system.

- All the sub processes are executed in accordance with the required operations to confirm the production as per the Production order.

Creating a Production Order Directly from Stock Requirement List

A Production Order can be created in the following ways.

Using Planned Order Number

Use T-Code: MD16 or go to Logistics → Production → Production Control → Order → Create → From Planned Order

Without Referring the Planned Order

Use T-Code: CO01 or go to Production → Production Control → Order → Create → With material

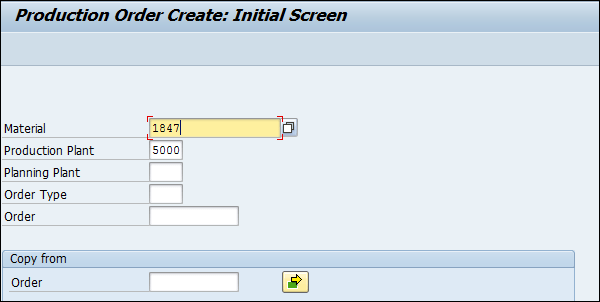

Enter the following details −

- Material code for which the production order needs to be created.

- Plant Code.

Click the tick mark in the above screenshot.

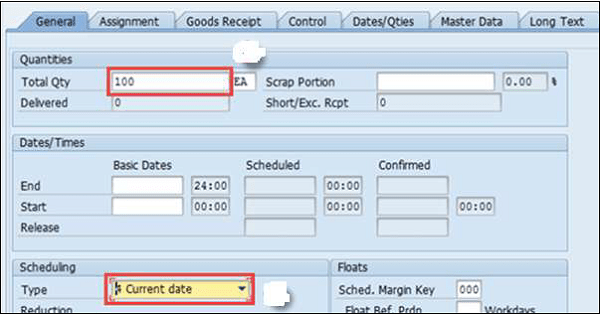

In the next window, input the order quantity. Under Scheduling, select the option current date as shown in the following screenshot −

Click the tick mark at the top of the screen to confirm and the system will then copy BOM and Routing data in the order.

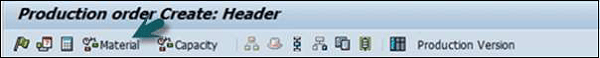

To release the order, click the Release flag at the top ![]() and you will get a message Release carried out.

and you will get a message Release carried out.

![]()

Click the Material button to check material availability.

Click the save icon at the top and you will get an Order number saved in the system.

Using Planned Order Number

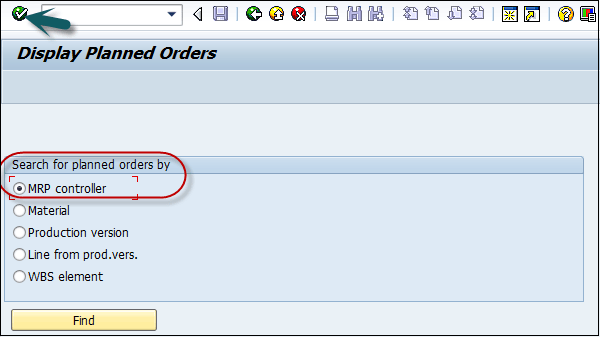

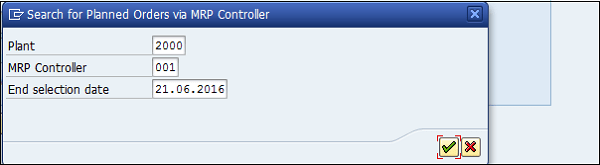

Use T-Code: MD16. Select MRP controller from the list and click the tick mark.

In the next window, enter the following details −

- Plant code

- MRP controller

- End selection date till all planned orders will be extracted.

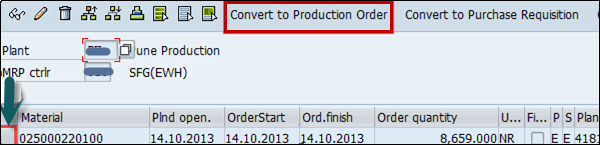

Select Planned orders that you want to convert into Production Order.

This will create Production Orders in the system.

Leave A Comment?

You must be logged in to post a comment.