Purchasing is a component of SAP MM module and its process can be roughly depicted in below diagram.

MRP (material resource planning) creates procurement proposal and later gets converted into Purchase Requisition. Next step is assigning source to Purchase Requisition, and release of Purchase Requisition. The PR gets converted to Purchase Order and upon goods receipt an invoice receipt can be done to complete the purchasing process. Additionally payment is processed (in FI module).

Procurement doesn’t have to start by the MRP, it can be initiated by consumption based planning or by direct creation of PR or PO.

MRP is a system function to determine the material requirements on both the material and BoM level. A BoM (Bill of Materials) is a list of components and subcomponents a single material is consisting of.

One of the mere basic documents in Purchasing in SAP is a purchase requisition.

Purchase requisition

Purchase requisitions can be created automatically by system or manually. They can be converted in purchase orders but only upon release (approval of purchase requisition).

We will cover several topic in this leson that can help understand and create the purchase requisition.

Number ranges in purchase requisitions are required just as in other document, for the purpose of assigning the document number to new created documents.

Later, these number ranges are being assigned to different document types we can define to be used in purchase requisition processing.

We will also cover requirement tracking number which is basically a number/letter combo which can be uniquely assigned to multiple documents in order to track certain important requirements.

You will se how the source determination works and why it’s useful, as well as how this source can be assigned to our purchasing document.

Finally, you will find out how to process the purchase requisition, from its creation until converting it to a purchase order.

Number ranges for Purchase Requisition

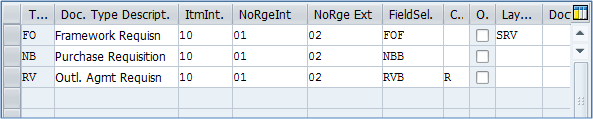

Assigning of number ranges for purchase requisition works on document type. Several different number ranges can be created and afterwards assigned to a specific purchase requisition type.

This is done in customizing. Requisition document types can have two number ranges assigned. One internal and one external range are assigned to each document type. Internal number ranges are being automatically incremented by the system, and external are assigned manually.

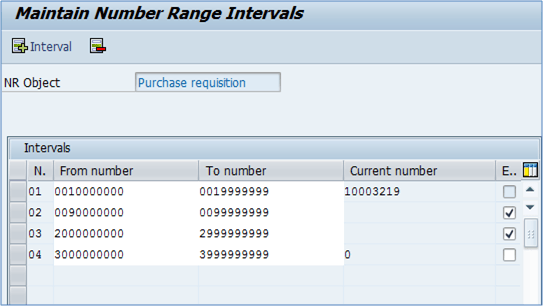

Screen below represents a list of number ranges for purchase requisition.

From number is the first number in the range, To number is the last available number adn the current number is the last assigned number to a document.

In addition, there is a check box indicating if this is an external number range.

For example, an internal number range can be defined as a range from 20000000 to 30000000, in this case documents of the document type that is assigned this interval will be numerated starting from 20000001 and will be incremented by 1 for each new document created. The last number available for this interval will be 30000000, and if your documents fill up the entire number range it has to be extended. It will rarely happen as it would mean that you would have 10 million purchase requisition documents.

Document type definition

Document type definition is an action of defining different document types for a purchase requisition. It is useful in grouping purchase requisitions and specifying its use in more detail. For example, we can have standard PRs, subcontracting and stock transfer. Every document type suits a special need and is configured to be used in that way.

In document type definition, you can define a number of options. Number intervals (internal and external), item interval, field selection key, control indicator, overall release indicator (defines if all the items in PR are released simultaneously or individually).

Standard Purchase Requisition document type in SAP is defined in all installations as NB.

Requirement tracking number

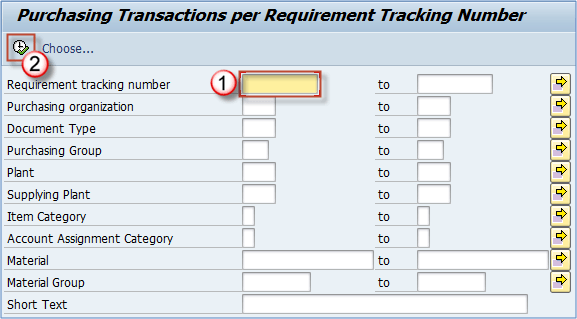

This number is used for tracking specific requirements. It can be entered during purchase requisition creation and is copied into purchase order document. It is maintained on item level and items can be selected by this number in several reports like MELB.

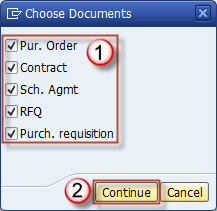

- Execute MELB transaction.

- Click the Choose button.

When you click Continue, you will be back to the initial selection screen.. You also have a variety of select options and should choose the most suitable options to narrow the search.

- Enter requirement tracking number(s).

- Execute.

You will be presented a list of documents containing the tracking number.

Source determination

Source determination assists in finding the most suitable source for a requirement, for example, it can suggest which outline agreement, which internal procurement source (plant) or which vendor can be used for ordering specific materials at given time.

Source determination take various data as parameters for the actual determination process. These include Outline agreement, Purchase info record, Plant in our company, Quota arrangement, Source list.

All this is taken into account while determining the best possible source for a requirement.

First check is done via Quota Arrangement where system determines if there is a suitable source with the relevant quota arrangement for the material, and if suitable source is found it is selected, and additional search for the source is aborted.

If not, system takes source list into account and searched for valid sources there. A source list consists of fixed and blocked records. Fixed records are for fixed vendors for specific material valid for a certain period. Blocked recordscannot be used as a source while they are in this status.

Finally system looks up the outline agreement and info record for credible sources and assigns them the requisition. You have seen in the previous lesson what is a purchase info record, and outline agreement is a scheduling agreement or contract which is also used in the source determination process as input information.

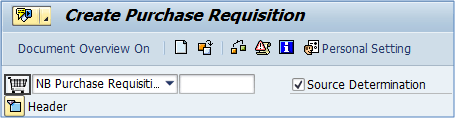

To use the source determination, you need to tick the Determine Source check-box on the pruchase requisition initial screen.

Assignment of source

System can perform background or foreground source assignment.

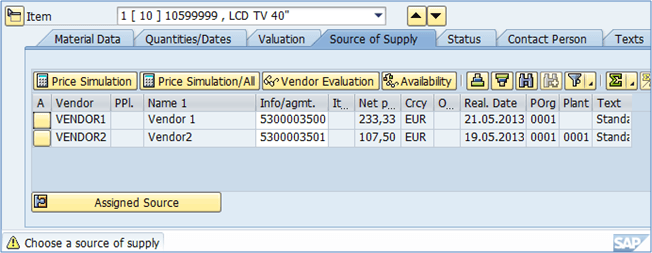

If the search is done in the foreground mode, and more than one valid source is found, a selection list appears from which user should select the appropriate source. If only one suitable source is found, it is assigned automatically.

If the search is done in the background, a single source must be determined and to accomplish that the system will perform various functions in the lookup.

For example, outline agreements have priority over the purchase info record source and in case of conflict an outline agreement source is selected.

If more than one valid source is found in outline agreements, unique valid source will be the one for the regular vendor, and if neither record is for a regular vendor, source will have to be determined manually.

You can see how two sources are offered by the system, from which we have to choose the better manually.

Leave A Comment?

You must be logged in to post a comment.